|

|||||

FlyingRC.net is a

Veteran-Owned site.

|

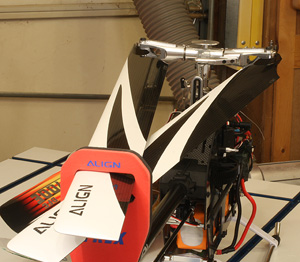

The Align T-REX 700E PRO DFC is a great looking helicopter that flies and performs better than I anticipated. Click image to enlarge |

Align T-REX 700E PRO DFC Flybarless Helicopter

My heli inventory gets bigger – literally

Text, photos and video by Tom Hintz

Posted – 2-11-2014

For months while I dutifully practiced hovering and the occasional tentative forward (short) flight with my Trex 450 Pro friends at the field kept telling me that the bigger helicopters flew “better” not so subtly hinting at easier. I eventually took their increasingly loud hints and sprung for my T-Rex 550E PRO DFC and within two weeks was zooming around the sky much to the amazement of even those who predicted how easy it would be.

Since then I have been eyeing a friend’s Trex 700 wondering if that next step bigger would be easier yet. Then I noticed the Align T-REX 700E PRO DFC that sported new features with an 800 motor. I wondered if Align added that motor specifically to close the deal with me because if they did it worked. Later that day I had the Align T-REX 700E PRO DFC kit and other needed parts on a plane headed my way.

The Basics

The Align T-REX 700E PRO DFC kit (#AGNRH70E09X) comes with a remarkably stout 520kV /800MX brushless motor and 700m 3G carbon fiber blades. You also get the 105mm 3K carbon fiber tail blades that are powered through the torque-tube-driven tail gears. That whole assembly gets secured to either the 3K carbon fiber tail boom or the aluminum tail boom, both of which come standard in the same box. I’m not sure why they pack two tail booms in this kit but I would soon be very happy they did.

|

|

You get these very nice carbon fiber 700mm blades (left) with the kit. While the blades look (and are) huge the 800 motor (right) swings them with ease. Collective on this helicopter has LOTS of authority! Click images to enlarge |

|

The Align T-REX 700E PRO DFC is 1350mm long, 360mm tall and 208mm wide. The main rotor diameter (700mm blades) is 1582mm and the tail rotor diameter is 281mm with the supplied blades. The motor has a 12T pinion driving an 112T slant-cut main gear. The 104T autorotation gear is also slant cut. All up weight with the motor (no batteries) is 2800g.

DFC Head

My T-Rex 550E PRO DFC showed me the speed-gaining value of the DFC head design so I never looked at a 700 that was not DFC equipped. My new Align T-REX 700E PRO DFC has the new head style with lots of beef where it counts to hang onto those big blades when I do stupid stuff in the air. Of course the DFC head is lower so there I less drag which means I can go faster whether I should or not. Align says that this head is more responsive and I would come to believe that beginning with the first flight. I’m like a D & ½ pilot so am not likely to stress the hardware as far as it will go and that is fine with me.

The swash and linkages all look to be first rate. I would like to see true turnbuckle adjustments on all swash plate links but they remain aftermarket pieces at this point. The direct to swash links on the Align T-REX 700E PRO DFC do eliminate the complexity and weight of the older pull-pull hardware. I also like that the swash anti-rotation guide is lined with a plastic-looking material that helps reduce wear and should get rid of any little metal on metal rattling that might have been coming from the previous metal on metal design.

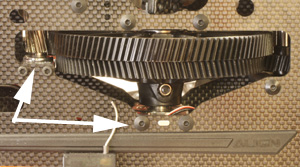

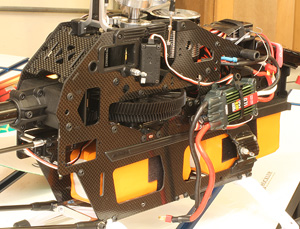

The servos are now mounted directly into the upper two bearing blocks on the Align T-REX 700E PRO DFC for a much cleaner looking and more rigid structure. Align also increased the main shaft length and added a third bearing block below the gear (and pinion) to help it resist deflection under the power of that 800 motor. They also top mounted the motor to move the CG (center of gravity) closer to the rotor blades.

All of this innovative hardware is mounted between the high-end and remarkably strong carbon fiber side plates. Align redesigned these plates for the new cyclic servo placement but also widened the base at the front to make sliding the batteries and wires into place easier. A spring-loaded latching mechanism keeps the batteries in position and I would accidentally stress test this system and find it to be very secure.

|

|

The new bearing blocks (left) put the servos directly under the swash for a cleaner mechanical layout and crisp response. Note the bearings below both the main gear and pinion (right) to prevent movement under the tremendous power of the 800 motor. Click images to enlarge |

|

There are any options when installing the electronics but the forward bay offers plenty of room for my BEC and that leaves the sides open for my customary placement of the speed control. Align also added a lightweight H-shaped plate at the top rear of the chassis as another place to mount electronics if you choose.

Assembly and Setup

If you have built an align helicopter in the past the Align T-REX 700E PRO DFC will not be a big challenge. In part the larger size of the Align T-REX 700E PRO DFC components makes putting them together easier and the instructions though typically cluttered, do walk you through the process in a logical order.

One thing newer Align T-REX 700E PRO DFC owners must be wary of is that assemblies in the package may be “assembled” but little if anything is actually tight. You have to take those things apart, clean the fasteners of oil and apply thread lock where needed. I know that putting the various assemblies together at the factory makes it easier for us to know where all of the bearings and washers go but I occasionally hear of unsuspecting folks who assumed that the assemblies were “permanently assembled” having a helicopter start taking itself apart in the air. As we will see, I managed to do something similar myself.

The physical setup of the Align T-REX 700E PRO DFC is not difficult. The most complicated tool you really need is a good digital caliper for setting the swash link lengths. You also need a swash plate leveling tool. Some people use a tie wrap secured to the main shaft to make sure all three points of the swash plate are level but I like the leveling tool as it is more precise an lets you check these three important points throughout the cyclic range more easily.

I Messed Up

|

|

The forward bays (left) gave me lots of room to install my BEC and its battery. The super-tough side plates are large (right) and make installing the ESC simple plus it gets lot of air. Click images to enlarge |

|

While installing the tail boom I noticed that the hole on the side where the locking bolt screws in was not perfectly aligned with the corresponding hole in the gear case. I probably could have forced the bolt in but decided to loosen the four bolts that clamp the housing on the tail boom so I could align the holes correctly. Then after installing that locking bolt I appear to have left the four bolts loose. I don’t remember if I stopped for something else or simply forgot to re tighten those bolts but it became obvious that I did leave them loose.

When I took the Align T-REX 700E PRO DFC into the yard for the first hover test I realized that the rudder servo was reversed so I fixed that in the radio. Later before going to the flying field I went through the BeastX setup again to check my cyclic range and re-bind the radio. In that process there is a tail correction sensor setting that I had reversed but didn’t notice it until I lifted off at the flying field.

Maiden Flight

My rush to finish the Align T-REX 700E PRO DFC and get it in the air on my next visit to the field nearly cost me dearly. On the first lift-off it rotated hard to the right. I got it back on the ground after just one rotation but that sheared off the tail rotor blades when the vertical stabilizer flexed when I stuck it in the ground.

Unable to see and other damage with my friends 700 tail rotor blades installed I again took off and this time the Align T-REX 700E PRO DFC flew pretty well. It still had a bit of tail motion (nose left) but was easily controllable and that seemed to go away altogether in forward flight. Then while making a left hand turn the tail boom snapped off. Because I forgot to tighten the four bolts that clamp the boom in place it was able to work back and forth until it fatigued and snapped. I did hit throttle hold and made a very poor attempt at an autorotation. The impact killed the landing gear, crunched the canopy a bit, broke one of the DFC links and one main rotor blade (the one that hit the tail boom) was trashed as well. Surprisingly, everything else was fine. Back at the shop I ordered the parts and had my Align T-REX 700E PRO DFC ready for attempt #2 the following Saturday.

Click Here to see the story on the crash and more on the damage.

|

|

Align expanded the lower portion of the frame (left) to make it much easier to slide the batteries and their cables into locked position. Very cool idea. I also used the optional Align series adapter (right) that lets me plug my two 6S packs into one side and then the ESC into the other. Very clean and no special wiring of the batteries! Click images to enlarge |

|

This time I had gone over all of the bolts at least three times and had a friend who also flies an Align T-REX 700 go over them one more time. Now confident my sort of new Align T-REX 700E PRO DFC would fly without shedding parts I set it out on the field for takeoff.

From the time I lifted off the Align T-REX 700E PRO DFC felt very different from my T-Rex 550E PRO DFC. The Align T-REX 700E PRO DFC has more collective “power” but overall flies very smoothly. I emphasize the collective power because I am not sure if it is actually pure power or just the Align T-REX 700E PRO DFC being more sensitive to collective inputs. Either way I had to learn to be more restrained and precise with the collective inputs and made good progress with that by the third flight.

I got in four flights with the Align T-REX 700E PRO DFC on the second day out and have to say that I am impressed. This helicopter flies very smoothly, very stable yet it responds to control inputs with authority. As I became more accurate with my collective use, rolls, flips and loops were getting much smoother and better looking. Holding the Align T-REX 700E PRO DFC inverted at the top of loops and even flying it across the field inverted was easy once I got used to how much negative collective it needed to hold an altitude.

Conclusions

If we put my mistakes aside the Align T-REX 700E PRO DFC is a very nice helicopter that is easy to assemble, setup and fly. I am certainly no 3D pilot but the Align T-REX 700E PRO DFC is making the learning process a bit easier with its power and smooth flight.

Takeoff and landing with the Align T-REX 700E PRO DFC are steady and predictable. If anything you have to be a little restrained when lifting off as the power available will pop the Align T-REX 700E PRO DFC into the air quickly which is fine if that is the plan. Otherwise it can be a bit surprising.

Video Tour |

|

My errors during the initial setup caused the crash but that incident showed me how tough the Align T-REX 700E PRO DFC really is. Nothing demonstrates durability more than smacking a helicopter into the ground and in that incident the Align T-REX 700E PRO DFC was a pleasant surprise when it came time to order repair parts.

The only downsides to the Align T-REX 700E PRO DFC are the canopy mounts and swash linkages. This helicopter used four pin-style mounts with small hairpin-type clips that lock the body in place. I would love to see pushbutton latches at least on the rear mounts. The swash linkages once again are not true turnbuckles but should be. Adding the turnbuckle threading would make setup more precise and much easier to do. I will be looking for aftermarket turnbuckles for my Align T-REX 700E PRO DFC but I think Align could finish off an already superior helicopter with these pieces from the factory.

All together I have about $1300 in the Align T-REX 700E PRO DFC in the air. That includes a new Spektrum AR7200bx BeastX receiver and satellite RX, the Castle ESC and BEC and a set of Align servos as recommended in the manual. You might be able to beat that with a combo kit but when I bought my Align T-REX 700E PRO DFC I could not find a combo that was in stock that did not force me to buy the 3Gx Align flybarless system. I personally am not a fan of the Align flybarless system but there are many out there who do like it so you have to make that decision on your own.

If you are considering moving up to a 700-class helicopter I think that the Align T-REX 700E PRO DFC should be at the top of a very short “must see” list. Align continues to impress me with quality kits that produce tough, easy to fly helicopters. With the low DFC head the Align T-REX 700E PRO DFC is both fast and great looking in the air. The canopy is easy to see with is bright colors and the quality airbrushing makes it look great on the bench as well.

See the Amainhobbies.com Align T-REX 700E PRO DFC product page

Have a comment on this review? –Email Me!

All Flyingrc.net written, photographic and drawn materials are property of and copyright by Tom Hintz and Flyingrc.net 2013-2020 Materials cannot be used in any way without the prior written permission of the owner.

Privacy Statement