Text, photos and video by Tom Hintz

Flight video by Clark Ponthier

Posted – 8-5-2015

When the muffler on my RedwingRC 50cc YAK 55 cracked I began looking for a tougher, more reliable replacement. When I asked people I know and cruised RC forums Bisson Mufflers went to the head of the class. Located in McKellar, Ontario, Canada Bisson Mufflers may not be as widely known as some other brands but they are well regarded by hard core RC pilots who appreciate dependable quality for their planes. Bisson Mufflers are available through some retailers or through their own web site and I include a link at the end of this review.

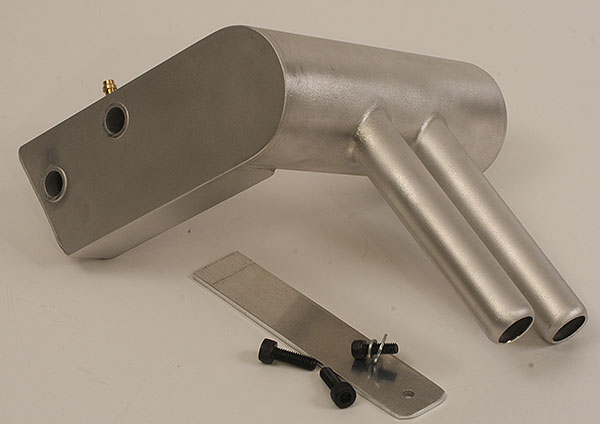

This all aluminum wrap around Pitts style muffler appears very well made everywhere you look. I also like that it comes with a support strap to stabilize the typically free end of the can for long term durability. Many of the Bisson Mufflers are available with the down tubes at 15 or 45-degrees. I chose the 15-degree model for my YAK. The down tubes are also longer than many so the exhaust is well outside of the cowl without having to add extensions.

Another option with Bisson Mufflers is a reduced sound level version due to additional internal baffling. The club field that I fly at does not currently have a sound rule but I can’t see quieting my planes a little as anything but a positive move for the future.

Where many wrap around mufflers use welded-in tubes to accept the pressure of the mounting bolts the Bisson Mufflers apply mounting pressure only through the mounting boss itself. The tube welding into the header are for access to the mounting bolts and do not carry any pressure themselves. Full-width aluminum tubes can distort or collapse, either of which can cause the muffler to loosen.

A year or so ago I stopped using gaskets on my mufflers in favor of purpose designed high temperature silicone gasket maker. I was happy to see that Bisson Mufflers also warns against using gaskets and recommends the high-temp silicone gasket material.

The label instructions say to apply a thin layer of the gasket material on both the engines’ mounting flange and the boss on the muffler. Then mount the muffler but only apply enough pressure to begin squeezing the gasket material out. Let it sit for an hour and then tighten the bolts down.

My Bisson Muffler came with an aluminum strap that stabilizes the free end of the can and virtually eliminates the vibration that can work on welds and the metal itself over time. The strap bolts to the can using an included bolt that secures the strap to a threaded bung installed during production.

The other end of the strap goes over the lower right motor mount bolt. You have to bend the end of the strap to fit your engine and trim the end but that all took me about 10 minutes to complete. The result is a very strong mounting system that can withstand the vibrations of our modern gasser one lung motors.

The Bisson Mufflers instructions call for running the engine up to temperature a couple times after installation is complete and re tightening the bolts to be sure you have them adequately snugged down. I ran the YAK with its new Bisson Muffler in the yard twice to take the muffler through a couple heat cycles and tried tightening the bolts with the muffler hot and then again when it cooled off. Because the mounting boss is so substantial through the whole heat cycle process I added at most another ¼ turn to the bolts and as of this writing the muffler remains as tight as the day I finished the installation.

I don’t have a sound meter and that’s OK since the vast majority of you don’t either. More importantly neighbors to our flying fields will also be judging the sound impact by how our planes actually sound in that environment.

During the first flights with my RedwingRC 50cc YAK 55 and its DA50R motor the Bisson Mufflers sounded noticeably quieter than the old wrap around muffler. I also noticed that the sharpness of the sound was dramatically reduced which makes the overall sound seem quieter yet.

The additional baffling that reduces the DB also increases back pressure slightly. During the first three flights with the Bisson Mufflers installed I had to lean the high speed needle just a little to regain the power and RPM the DA50R had before the installation. Since those adjustments the DA50R has performed fine and there is no discernible loss of power or throttle response with the same Vess 23B prop that I had always used on this plane.

I also noticed that in flight the echo we normally get off a tree line directly to the front of our flight line and about 700 feet out is much harder to hear with the Bisson Muffler. I am not sure if this is just the high frequency reduction reducing the echo or if the overall sound is doing it. Whatever is responsible the sound is reduced and that means that what people around the flying site hear is reduced as well.

If you need a good muffler for your gasser (or glow engines) check out Bisson Mufflers offerings. Everything I have heard and now what I have seen for myself indicates a quality product that is designed to last a long time. I like anything that I can put on my planes without worry about it falling off, apart or otherwise failing.

The low DB Bisson Muffler in this review for my DA50R sells for $135.00 (8-4-2015) with a regular version selling for $115.00. Neither is a bad price considering what mufflers in general are selling for these days and I think it is downright cheap for the quality and longevity you get. Add to this the 1 year warranty against materials and defects and the price gets better yet. Incidentally, within that year if a Bisson Muffler cracks (no crash damage) simply contact them directly to send the muffler along with proof of purchase and they will fix it up for free.

Visit the Bisson Mufflers web page – Click Here

Have a comment on this review? –Email Me!