One of my first larger planes I decided to install a 50cc-equivelant electric motor

in my Yak. It was VERY fast but with the batteries needed it landed like an ill

pickup truck.

Text, photos and video by Tom Hintz

Posted – 6-9-2014

NOTE: I have updated the YAK with a DLE 40 Twin gas motor. Click Here to see that review.

I have always liked the looks of the Russian-designed YAK 54 so when I started cruising the RC world for a larger plane the Pilot 26% YAK 54 caught my attention. I did consider other planes from other manufacturers but after walking the 3D line at the 2014 Joe Nall event Triple Tree Aerodrome and seeing a bunch of Pilot aircraft, including a couple Pilot 26% YAK 54’s I went back to the Chief Aircraft tent and bought the YAK in this review.

The Pilot 26% YAK 54 has a wingspan of 73" (1.85m) with a wing area of 1031 sq in (6652 sq. cm). The fuselage is 65.8" (1.67m) long overall and this dimension was important to me because of the car I would have to carry it in.

The Pilot 26% YAK 54 is supposed to come in with flying weight of 10.5 lbs. (4.8kg) with the 26 to 35cc gas engines it was designed for. My Pilot 26% YAK 54 came in a bit heavier because of the electric conversion but that has not hurt performance in any measurable way.

The Pilot 26% YAK 54 is an ARF that actually sticks with the Almost Ready To Fly nomenclature. In addition to appearing very well engineered and jig built the quality of all the parts and assembly is first rate. All of the hinging is already done, including gluing with the exception of having to install the rudder and even that comes with the hinges glued into the rudder. All you have to do is apply glue to the other half of the hinges and slip the rudder in place on the vertical stabilizer.

The motor box is done with the exception of the top which is left unglued to make installing the motor standoffs way easier. Though I was putting an electric motor in this plane the open-top motor box proved to be important.

The Pilot 26% YAK 54 kit includes a full set of fiberglass control horns and servo arms. They even throw in tiny bolts and nuts to secure the servo arms to the large round arms supplied with the servos. This kit calls for 160oz-in servos so I used 5 HiTec HS-5565MH Coreless High Voltage Metal Gear High Speed Digital Servos (two elevator servos) that produce 194 oz.-in at 7.4 volts each. With any kind of luck my Pilot 26% YAK 54 was going to be quick and the last thing I want is control surfaces that stall out because of weak/cheaper servos! Another nice thing is that Pilot cuts real servo openings so my Hitecs’ dropped right in with no modifying of the holes.

Before you ask, yes, this is too much

power for this plane.

Something else I was happy to see was that Pilot includes all control surface linkages. All of those links terminate (both ends) in nicely sized ball links to eliminate play while being very secure with the bolts and lock nuts that come loosely installed in each of them. Even more impressive is that the heavy steel rods connecting the ball links are true turnbuckles that can be tweaked tiny amounts with the included wrench. These links made setting the Pilot 26% YAK 54 up simple, very quick and dead on perfect. It also means that tweaks at the field are just as easy because I don’t have to take anything apart.

Another YAK-related feature I love is the half-wheel pants (spatz) that are part of this planes distinctive look. I was also pleasantly surprised to find machined aluminum wheels in some type of foam rubber tires as standard equipment. And the wheels have brass sleeves that run on the smooth axles. (I would find out that if you don’t grease these during assembly they can make a frightening squeal later….) The wheels are 3”-diameter which is sufficient but I would love to see a 4”-diameter wheel on a plane this big. The one-piece carbon fiber landing gear looks good and proved to be sturdy including its mount that has aluminum brackets inside the fuse to spread out jars induced by less than perfect landings.

The only issue with the carbon fiber gear is that one side is tapered and the other side straight. I looked at the gear from all angles when I put the Pilot 26% YAK 54 together to get the tapered side to the rear. After a bunch of flights I became suspicious of the gear and after having a few guys at the field look at them the consensus was that I had them on backwards. I turned the gear around and the next time at the field my YAK seemed to handle better on the ground. I vote for a more pronounced taper, marking the taper side or not having a taper at all.

I searched quite a bit and could not find much info on converting the Pilot 26% YAK 54 to electric power. I was however able to find several people who were certain that this was a dumb idea. Not being scared of dumb ideas I thought that the smart plan would be to err on the high side of power. Since the Pilot 26% YAK 54 is rated for gas engines with up to 35cc displacement I wanted at the very least that much electric power. Then I came across the Great Planes Rimfire 50cc Electric Motor (Tower #LXXJW5) and thought that would fit in the pre-installed cowl so I ordered one. I also ordered the Great Planes Stand-Off Brushless Motor Mount XX-Large – (#LXYCG0) and a Xoar 22x8 PJA Series Beechwood Propeller (#LXZHY8) that they thought was the low end of the prop spectrum for this motor.

I was smart enough to use Castle's best

for this size motor.

Controlling all this power was going to take a substantial speed control so I got the new Castle Creations Phoenix Edge 160HVF 50V 160-Amp ESC w/Fan. Airflow through the Pilot 26% YAK 54 cowl looked good but I wanted to be very sure the ESC didn’t overheat and start reducing power or doing something else right when a bunch of power would be a great idea for a save.

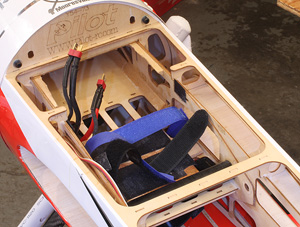

While this motor has options on the power needed to operate it I already had a pile of 6S packs so used them. My Pilot 26% YAK 54 system runs on two 6S, 5000mAh LiPo packs hooked up in series to produce a 12S, 5000mAh pack. The motor is rated for up to an 18-lb plane, I expected the YAK to come in around 12-lbs and I was at least starting with the smaller prop so I was hopeful of getting 4 or 5 minute flights with some on and off the throttle flying.

Since the Castle Creations Phoenix Edge 160HVF doesn’t have a battery eliminator circuit built in (I wouldn’t use it anyway for this plane) I bought a pair of LiPo 7.4V, 2700mAh packs to power the receiver and those big servos. I used a Spektrum Dual I/O 3 Wire Switch Harness (#SPM9531) to connect the batteries to a new Spektrum 8-channel receiver with a satellite antenna.

Frankly, I was a little spooked by how large the Great Planes Rimfire 50cc Electric Motor actually was when I got it. That got me thinking about the firewall in the motor box. I was already pretty sure that I would need some tail weight with this setup so I decided to laminate a piece of 3/8”-thick plywood to the backside of the firewall. This way the thrust angle Pilot had built into the motor-box would remain so I wouldn’t mess up the flying characteristics.

I am thankful that I spent the $49 on the motor standoff kit as it really made this installation a no-brainer. Because the cowl is factory installed I measured from the firewall to the front edge of the cowl and then subtracted the distance from the back of the mount plate on the motor to the surface of the prop washer from that to get my standoff length. Using parts from the kit as is I was able to come up 1mm over what I wanted ideally. I can live with that since it meant not having to do any machining!

The standoff kit came with a template for the mounting holes that has vertical and horizontal center marks which the firewall also had so alignment was simple. I drilled the holes, installed the blind nuts and went over everything inside the motor box with a layer of slightly thinned epoxy just to be sure. Then the top was trimmed to accommodate the built-up firewall and that was also epoxied in place.

The Castle Creations Phoenix Edge 160HVF is sort of large with the fan and all but it fit nicely in the underside of the motor box. I stuck it in place using Velcro and added a retaining tie wrap that is not tightened down on the speed control but rather strung as a limiter that won’t let the ESC fall off. I have since hammered the Pilot 26% YAK 54 all over the sky, snap rolls, knife edge spins etc. and the Castle Creations Phoenix Edge 160HVF is still right where I left it.

I was cautious when it came to securing

the battery packs.

The rest of the assembly process went just as prescribed in the downloaded manual. I am not a fan of putting pull-pull systems together but I do like how they work. The Pilot version uses heavy-duty steel cable and easy to work with. They have real ball ends with more than enough adjustment for me to loosen the cables a little later when a friend pointed out that I actually had them too tight. I did the suggested loosening (and moving the servo side in one hole to match the rudder mounting) and all is well with the rudder.

The Great Planes Rimfire 50cc Electric Motor weighs in at 44-oz so with the pair of 6S LiPos, my CG was forward of where the Pilot 26% YAK 54 likes it. I had anticipated this and had mounted the receiver and both battery packs at the rear of the canopy opening to maximize the effect of that weight but the CG was still forward of the laser-marked position at the rear of the spar tube. During the early flights I worked my way up to 2-1/2-oz of lead mounted on the tail wheel strut and the Pilot 26% YAK 54 got happy and lands smoothly plus the in flight balance feels very good. It tracks very well upright or inverted so I am leaving the CG alone to focus on tweaking the rest of the control setup. If a problem or tendency appears later I can always move the CG further rearward but so far the Pilot 26% YAK 54 seems to be very happy as it is.

Day one of flying the Pilot 26% YAK 54 went pretty well from the first lift-off when I discovered that it needed just two clicks of down trim to go straight and level. I rolled it inverted at about 45-degrees and 75% throttle and it had the slightest of downward arcs indicating that the CG was at least close. After flying it around a while and wowing everyone with its spectacular vertical performance I began shooting some landing approaches which went OK but did show me that the Pilot 26% YAK 54 likes a bit of throttle on short final.

The first time I set the Pilot 26% YAK 54 up for a real landing I found that the forward CG let it drop out of a glide nose first, hammering the landing gear way more than I liked but there was no damage. I took off again came around and this time kept the speed up with a little throttle and the Pilot 26% YAK 54 landed OK. It looked good but I knew I was holding too much elevator. I did fly the Pilot 26% YAK 54 a few times that first day with all of those flights ending with landings that were decent looking but using excess elevator.

Back in the shop I added 2-1/2-once of lead to the tail wheel bracket. The Pilot 26% YAK 54 is awkward when you try and balance it on the CG on fingers but it did seem much closer to the suggested location. I made no other changes to weight but did go through the controls and dual rates.

I left the full throw setting to “all I could get” at the elevators, rudder and ailerons. I dialed back the #1 dual rate position to 40-degrees on the elevator and ailerons but left the rudder on full travel. I dialed in the recommended “low rates” on position #2 on my dual rate switch and have used those throws exactly once. Way too dead for me. At this writing I am up to about 20-degrees for the low rates on the ailerons and elevator.

The next day at the field the Pilot 26% YAK 54 flew and landed great. The added tail weight had brought the CG to a happy place and landings are now very easy with a just a bit of elevator to hold a gentle flare as it touches down. I still managed to bounce it now and then but it’s a brand new airplane and I’m me so get over that.

The Pilot 26% YAK 54 snap rolls great, does very good upright and inverted flat spins. The knife-edge spins the Pilot 26% YAK 54 does at 50 to 75% throttle (over-sized motor remember) are absolutely frightening. Anytime I do a knife-edge spin everybody at the field is looking up to see the explosion that sounds to be on the verge of happening.

Harrier-type flying is just starting to get more comfortable for me though I continue to do it a couple of mistakes high. The Pilot 26% YAK 54 seems to want to drop wings more than my 60” Edge 540 but I am getting used to it and as I relax the wings are getting more stable. I am finding that the Pilot 26% YAK 54 likes far less elevator to maintain a harrier type move than I am used to but I am catching up.

The pure vertical performance of the Pilot 26% YAK 54 is what really grabs people’s attention. The other day several people who had not seen it fly came to the field. I took it up again, lifted off, pointed it straight up and got on the gas. You can hear the motor accelerate as it gains speed climbing straight up. When I landed many of those new arrivals came over and asked, “What kind of motor is in this thing!?!

I am using a pair of 6S, 5000 mAh battery packs and started out with the timer set to 5-minutes. If I do a lot of full-throttle flying I was seeing 25 to 30% remaining capacity. Do more partial throttle stuff like elevators, spins and harrier practice and 40 to 50% remaining capacity is common. I am going to experiment with smaller props as the 22 X 8 Xoar is dangerously close to the ground with the Pilot 26% YAK 54 up on the mains during touch-and-go’s. I have chipped a couple props so far so am going to try a Xoar 20 X 10, 21 X 8 and maybe a three-bladed prop. A smaller prop might stretch the flight time but for now 5-minutes is enough with a new plane that I have lots of money in. I love flying it but am very happy to get it back on the ground as well.

The Pilot 26% YAK 54 is a great plane. The ARF kit is first rate at least with many aspects of it being the best I have seen. The electric conversion went smoother than I anticipated but I used all good equipment which always makes these things easier. The performance is over the top in terms of power and aerobatic abilities.

I have a friend who is thinking about getting a Pilot 26% YAK 54 as his first big plane and as active as the YAK is, reducing throws really tames it down so an intermediate pilot should be able to handle it easily. Then after you get more familiar with it use dual rates to ease yourself into and more responsive aircraft.

Of course if the worst happens and you ding it up you can avail yourself of the very unusual Pilot program. Send them photos of the damage and a list of what you need to repair it and they cut the pieces and send them to you if you pay only the shipping! The shipping is from China paying for a small pile of balsa to be sent halfway around the world is way better than buying a couple of assemblies from just about any other company I know of.

When I am thinking of a new plane in the future you can be sure that I will cruise the offerings from Pilot first. They make good stuff at reasonable prices and I like that kind of thing in RC these days.

Visit the Yak page at Chief Aircraft (the US source for Pilot) – Click Here

Have a comment on this review? –Email Me!