A different idea for gas tanks turns out to be just what many of us needed>

Text, photos and video by Tom Hintz

Flight video by G. Jawhar

Posted - 1-28-2015

Fuel tanks for RC airplanes changed very little for many years. The shapes might vary somewhat but the rubber plugs and brass tubing that got the fuel in and out of them was largely the same across the market. Because of the rather simplistic technology pilots paid little attention to their fuel tanks - until they failed. Between aging internal lines, clunks falling off (or flipping forward) and leaking caps these older tanks grew more and more unreliable as they aged. Today there is new thinking in the RC fuel tank arena.

When I had what appeared to be fuel-related dead-sticks with my Aeroworks 50cc Pitts Python ARF-QB I started looking for alternatives and came across RotoFlow Fuel Systems. I searched for conversations on the RotoFlow Fuel Systems and discovered that those who had actually used these tanks often had several of them in their planes while the big majority of the detractors just didn’t like the idea despite not having used them. So goes the Internet.

The RotoFlow Fuel Systems tanks are made from polyethylene plastic because it molds well, is impervious to RC fuels and is tougher than the plane around it. While RotoFlow didn’t change the container material they did changed the shape and put an entirely different system within it. No more internal fuel tubing to harden and leak air. Also no more clunk on the flexible tubing to come off or get jammed forward in a hard landing or crash. RotoFlow really did have a better idea and then executed it very well. Also the RotoFlow Fuel Systems are compatible with gas or glow fuels without modification. Once installed there is no maintenance needed inside of the RotoFlow Fuel Systems tanks.

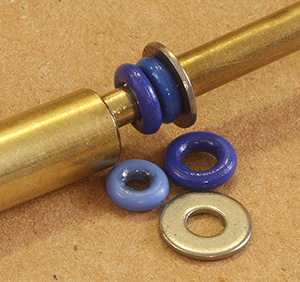

The mechanism within the tank consists of a brass tube running front to back where it is pressed into a boss molded into the tank body that seals that end. The front end is fitted into a machined aluminum cap with twin O-rings that guarantee a solid seal. A solid aluminum outer ring maintains the pressure on the neck to insure the seal while eliminating the outward pressure that frequently split more traditional tanks. If you have ever had a tank split and begin filling your fuse with fuel the RotoFlow Fuel System tanks will be of special interest…..

Near the back of the brass tubing is a rotating pickup assembly with a heavy brass pickup at the end of a 45-degree arm. Combined with the octagon shape of the tank that keeps the end of the pickup close to the back edge of the tank regardless of the attitude of the plane. That means a more consistent flow of fuel because the pickup remains in the deepest part of the fuel and stays away from the layer of foam engine vibrations can create.

The mechanism is way different from the

old line and clunk concept.

In researching the RotoFlow Fuel System for this review I noted that a common concern of those who had not used a RotoFlow Fuel Systems tank focused on the rotating pickup assembly, fearing that it would leak air at the main shaft even though they had nothing to prove that. To be sure if this part had been poorly designed or manufactured air leaks would certainly be a possibility. However the RotoFlow Fuel System uses a set of high-tech flourosilicone aerospace seals, doubled up on both ends of the rotary pick up and backed up with stainless retainers on either end. The expected life span of these seals (developed by NASA for their use) is 25 to 30 years! RotoFlow Fuel Systems are guaranteed for 3 years so they are obviously convinced the seals are not an issue.

RotoFlow Fuel Systems supplied me with an entire pickup assembly which let me pull it apart and look for myself. Being able to see how this system works and how it is assembled, I can see no reason not to believe that air leaks inside of the RotoFlow Fuel Systems tanks should be very low on the worry list for any plane equipped with this type of fuel tank. I think we should be more worried about something far more likely such as flying the plane into the ground or getting struck by lightning.

The fuel is drawn through the pickup and through several holes in the main shaft under the swinging pickup assembly. The holes are small but there are several so the total area of the opening means the fuel line will never be starved for fuel. The folks at RotoFlow Fuel Systems have done their homework.

The octagon shape of the RotoFlow Fuel System tanks made it easier to install in my Aeroworks 50cc Pitts Python ARF-QB. The only access to the fuselage interior is from the bottom so I had to put the RotoFlow Fuel System in upside down to have it right side up when the plane was right side up. The octagon shape let me run the vent line around the top surface of the tank and tape it down where it would not be compressed by the hook and look straps I used to secure the tank. I also taped a length of ½” foam to what would be the top of the RotoFlow Fuel Systems tank to give it a good layer of isolation from airframe vibrations.

The RotoFlow Fuel Systems tank came with the “pressure” nipple molded shut because many use a two line system with a T in the line that goes to the carb for filling. I like to use a separate line for filling so drilled that nipple open with a 1/16” drill and ran a line to the fuel dot on the side of the fuse.

Aside from it being a pretty tight fit getting a 32-oz tank in the fuselage the install went very easy. The barbs on the tubing connections are nicely pronounced so putting the line on and securing them with small tie wraps was easy but also very secure. I know 32-oz is a lot of as for a 60cc engine but I am NOT going to run out of gas. Bi planes are not fun to dead-stick on a good day so I want to avoid that situation whenever possible.

Space-age seals make this idea durable.

After finishing the install I filled the tank well over half full and let it sit right side up and then upside down, both for a couple hours to check for leaks. None were noted so I took the plane outside and fired it up without the cowl in case I needed to “coax” the fuel up to the carb. Once fuel reached the carb (seven choked flips) the engine started and was not a problem starting from then on. I had to lean the engine slightly with the cowl off but expected more adjustments will be needed with the cowl in place ready for flight.

At the flying field the first take-off began showing just how much the DLE-60 Twin Engine had richened up. I flew it about 8 minutes at varying throttle settings before landing and leaning out both the high and low speed jets 1/8-turn. Adjustments after subsequent flights would total about ¼-turn leaner on both screws and the engine still had a tiny bit of a stumble transitioning from low to high speeds but was very manageable. I will continue to tweak the carb the next time out.

The point of this is that the RotoFlow Fuel System tank is delivering gas to the carb more easily and more consistently and that was causing the carb to go so rich. That consistency remained regardless of the attitude of the plane, upright, inverted, pointed up or down, the prop speed changed only in relation to the load on it. The engine never seemed to sag or burble due to changing fuel delivery as it did before. In fact, everything I encountered pointed to the RotoFlow Fuel System tank providing fuel to the engine more consistently. When I am flying 17-pounds of bi plane consistent fuel delivery makes me way happy.

I think that the RotoFlow Fuel System tanks are a great idea that has been done right with the super-duty seals on the one critical component that could cause a problem if done cheaply. The design of the rotation system as well as the tank surrounding it means that the pickup will always be close to the tanks rear edge regardless of the planes attitude. Plus all of the major points of failures on more traditional tank designs have been eliminated.

As you might suspect RotoFlow Fuel Systems tanks are not the cheapest on the market, at least in their initial cost. A 10-ounce RotoFlow Fuel tank sells for $29.95 (1-27-2015) and the 50-ounce version $49.95. RotoFlow Fuel System tanks are also available in 12, 14, 20, 24, 32 and 40-ounce sizes. These tanks carry a three year warranty but their useful life should exceed that by a bunch. By eliminating the internal tubing and using seals with a 25-to-30 year life span means there is very little that can go wrong with these tanks so your cost-per-year will be substantially less than if you would maintain/replace the cheaper, more traditional tanks.

The combination of superior performance and long-term durability make the RotoFlow Fuel Systems tanks a must have for me. I think that before long all of my planes will be equipped with the RotoFlow Fuel Systems tanks because of the consistent fuel delivery and it makes perfect long-term financial sense. Plus I just enjoy flying way more when dead-sticks are few and far between.

Visit the RotoFlow Fuel Systems product page – Click Here

Have a comment on this review? –Email Me!